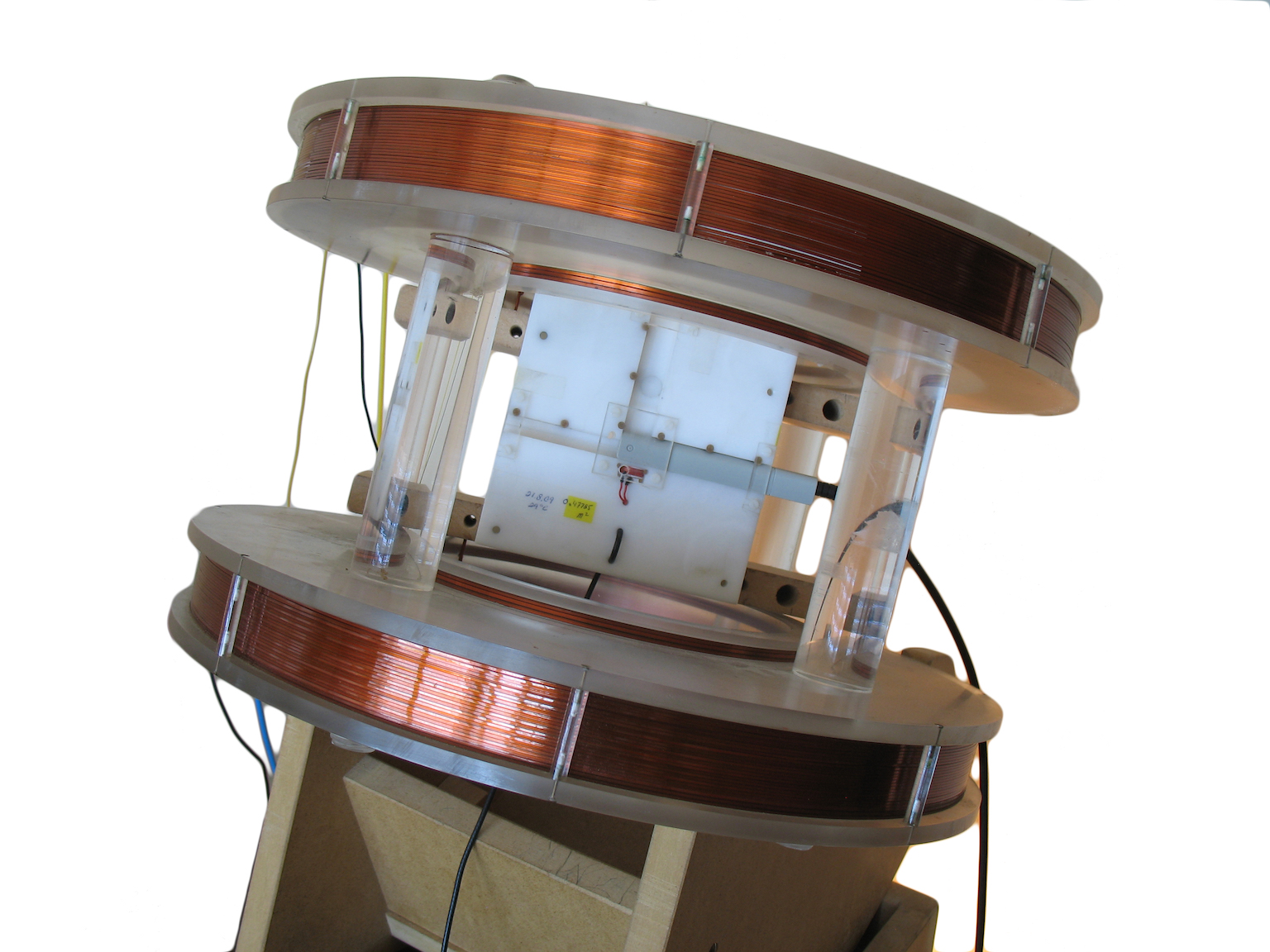

Three-Axis Hall Effect Magnetometer THM1176

3-axis magnetometers

Advantages

+ Triaxial integration of Hall sensors

+ Almost instantaneous

+ Adaptable sensitivity for medium to high fields

+ Easily integrable

+ Measures a single vector component of the field

Constraints

– Lower precision compared to NMR or fluxmeter

– Precise calibration is required

– Periodic recalibration is needed to compensate for drift

– Angular dependence introduces measurement error

Known since the late 19th century, the Hall effect is the most common method for measuring medium to high fields, across a wide range of applications.

In fact, sensor applications – proximity sensors, rotation sensors, current sensors, etc. – are economically much more significant than measurement applications and have propelled the Hall element into mass production.

A modern Hall element consists of a thin plate of semiconductor material. When a current is injected parallel to the plate, a perpendicular magnetic field causes the conductors to move left or right, resulting in a voltage difference between the left and right edges.

Sensitivity can be adjusted by varying the current; it’s possible to measure both positive and negative field components; and it’s straightforward to integrate such a sensor into a fully electronic measurement system.

To compensate for these physical effects, a Hall device must be carefully calibrated and periodically recalibrated.

Assuming linearity of response, calibration is usually performed at zero and at the positive and negative limits of the measurement range.

For zero field calibration, a zero Gauss chamber can be used. For high-end calibration, a high-field reference magnet is needed. For the ultimate reference, the magnet is controlled, or even regulated, by NMR.

To compensate for planar Hall effect or other sources of interference, highly complex 3D calibration and deconvolution are required. That’s why Metrolab advocates the use of triaxial sensors that minimize information loss.

If the response is significantly non-linear, calibration at one or more intermediate field values is necessary. To compensate for temperature effects, the entire calibration must be repeated at least at two temperatures.